52Xi-LA

52Xi-LA

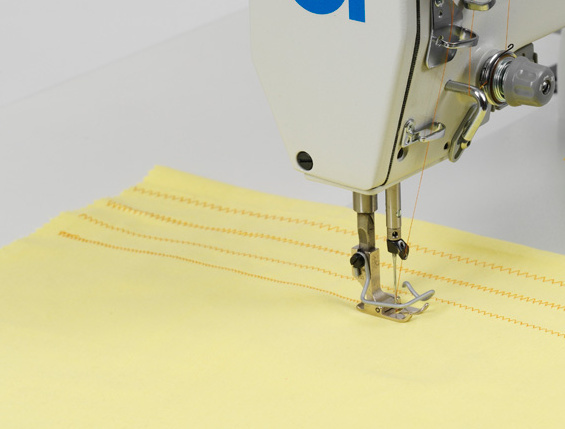

Long arm zigzag

Our standard zigzag machines are available in different lengths for light / medium weight applications. This ensures adaptation of our proven sewing technology for applications on large-sized workpieces.

■■ Thread trimmer (CLASSIC) ensures secured cutting, also for thick threads up to 20/3

■■ Modified lubrication and a reservoir in the machine arm reduce maintenance, guarantee the correct lubrication doses and protect the hook against wear.

■■ Optimized thread trimming system with adjustable bobbin break spring (CLASSIC version) for better stitching results

■■ Needle thread tension regulation for more precise tension adjustment

■■ Ergonomic bobbin winder with easier adjustment of max. value

■■ Improved working conditions for the operator by reduced noise level and less vibrations

■■ Modern zigzag setting device – easy adjustment of zigzag width with low force

■■ Easy stitch length setting – adjustment without lever by turn button

■■ Back tacking and needle position up/down via push buttons (CLASSIC)

■■ Use of incorporated mini motor and quick connection from the head to the motor (CLASSIC)

■■ Integrated LED sewing light (optional)

Long arm zig zag machines

■■ Various arm lengths available

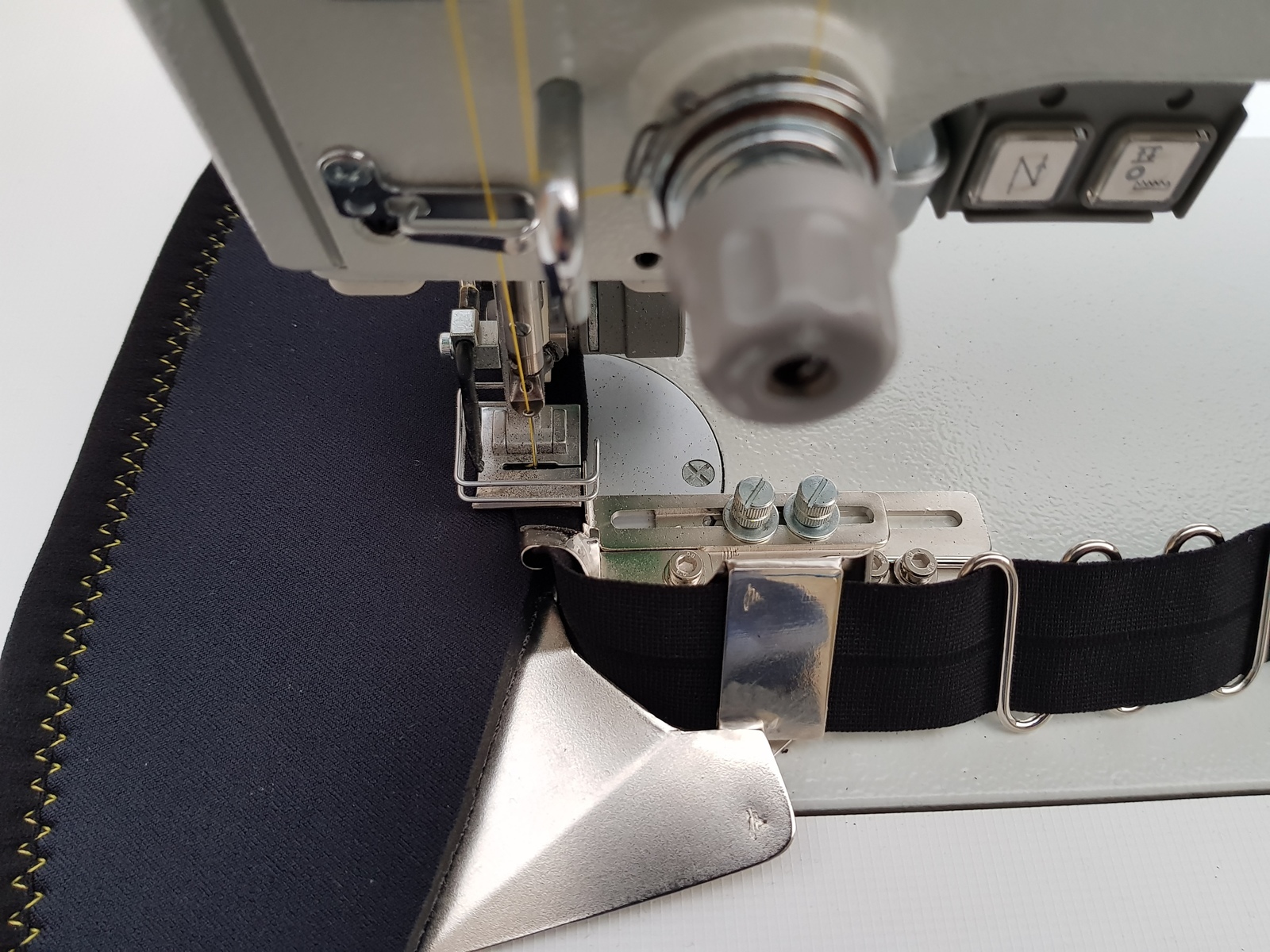

■■ Machines can be equipped with mechanically, or pneumatically driven puller (optional)

■■ Backtacking and foot lifting, pneumatically driven (optional)

■■ Needle cooling device (optional)

■■ Arm clearance can be increased to 183 mm (optional)

■■ Extra heavy stand + table top available (optional)

All types of Dürkopp Adler zigzag sewing machines are available as long arm machines

These machines are used for manufacturing and repairing large dimensioned workpieces, such as windsurfing sails, wetsuits, tents, awnings etc.

An intermittent puller, as optional equipment, allows a high performance. The feeding assistance from above avoids material shifting. Puller is available with different widths of feeding wheel.

Easy operating of backtacking and puller lifting by means of ergonomically designed push buttons.

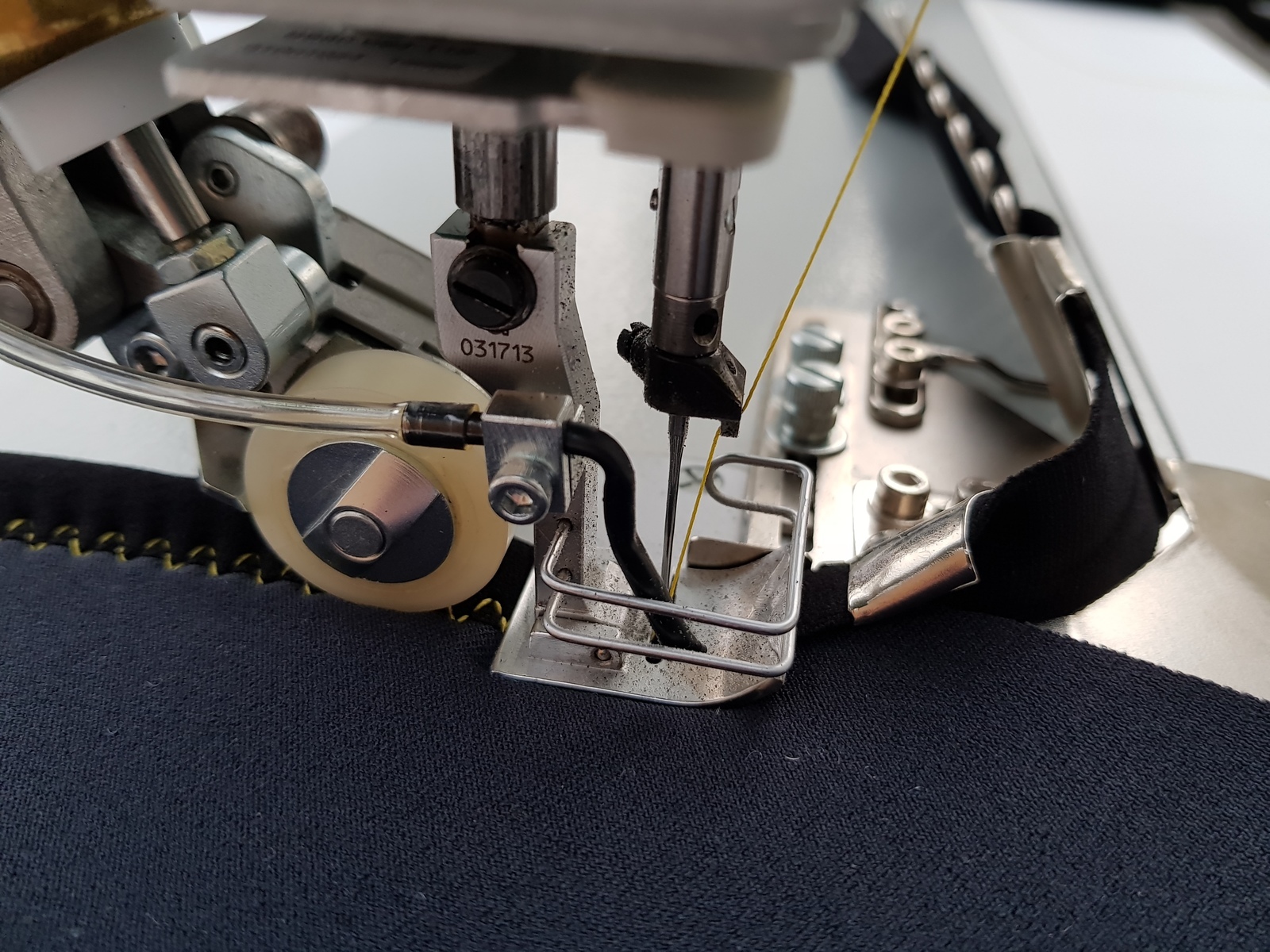

Sewing equipment for binding operations.