History of Minerva trade mark

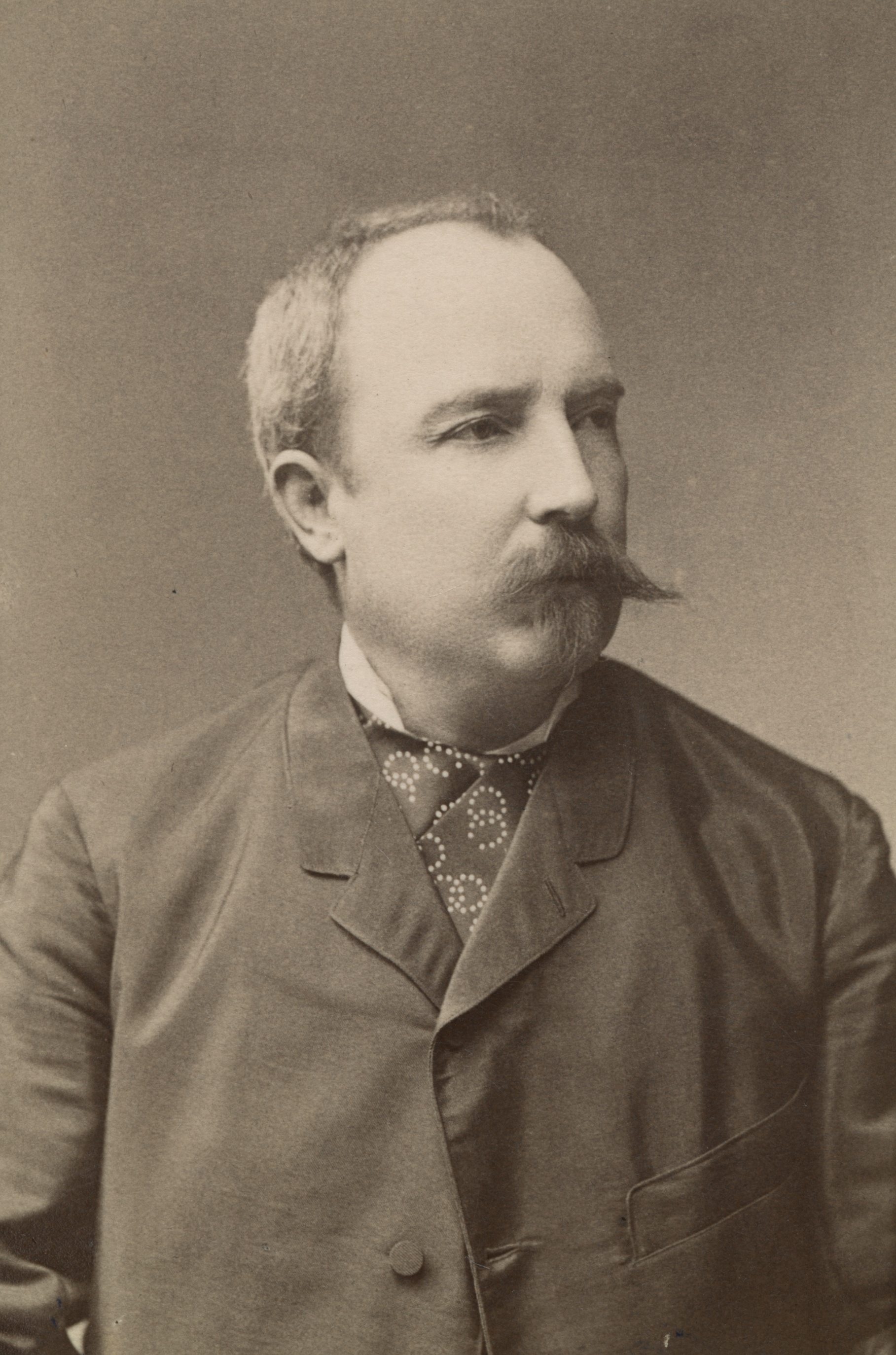

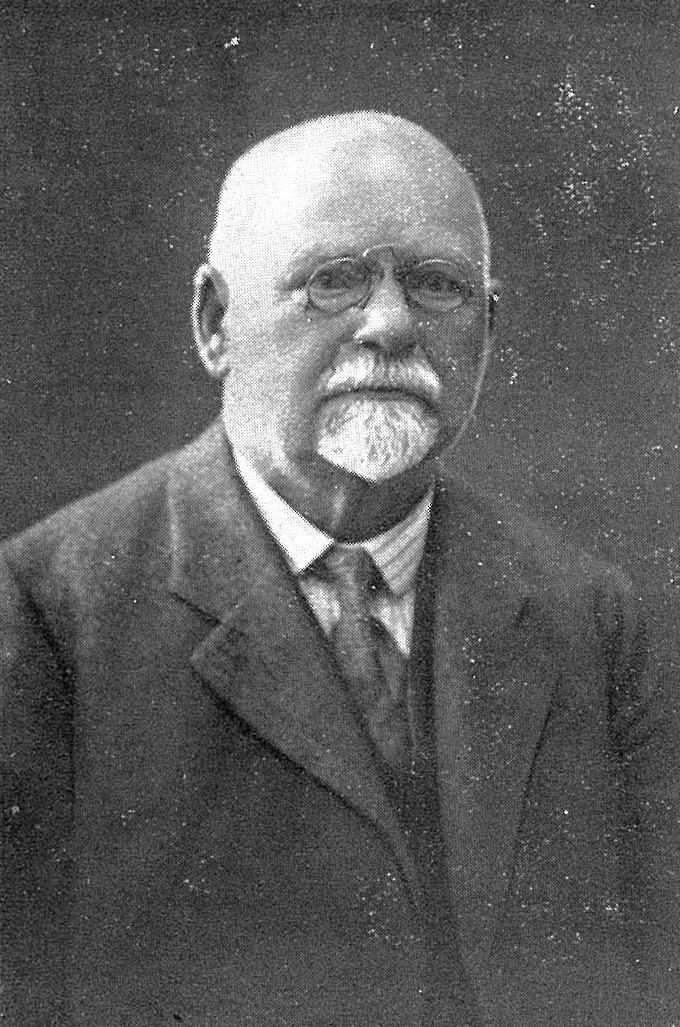

The history of the company MINERVA commenced with its founders, Mr. Emil Rezler and Mr. Josef Komárek. Emil Rezler was born in Železný Brod in Bohemia on 4. November, 1842. As a boy of fourteen, he went to Kopidlno to serve his apprenticeship at a mechanical workshop, where he was trained for a skilled lockmith’s craft. To improve his knowledge and skill, he left for Vienna in 1867; Vienna was the center of sewing machine production. lt was where he met Josef Komárek, and in 1881 they founded the company “K. k. priv. Nähmaschinenfabrik Rezler & Komarek in Wien” as a public company for sewing machine production. lt was the first Czech company for sewing machine production not only in Vienna, but also in the whole of the Austro-Hungarian monarchy. They had the MINERVA trademark registered in 1883, including the inscription “Meliora sunt bono inimica” (“Better is the enemy of good”) under the registration number 3297. A better-known form of this trademark is the one in an oval label registered in 1891 under the registration number 1284. This form of the goddess Minerva was cast on the side of the sewing machine stands.

|

|

|

|

.jpg) |

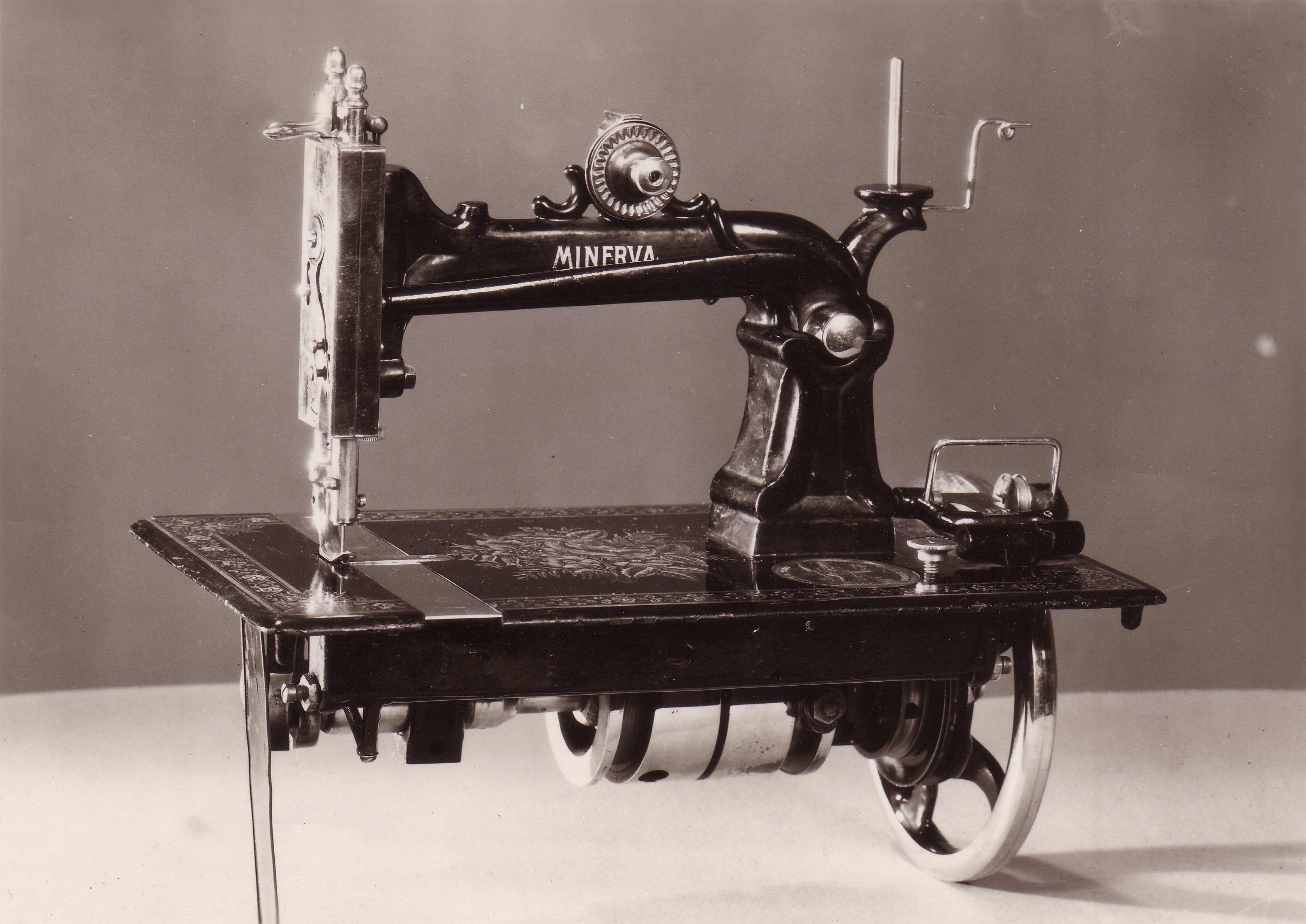

| Trade mark1883 | Mr. Emil Rezler | Mr. Josef Komárek | First sewing machines manufactured by Rezler & Komárek company |

The goddess Minerva was cast on the side of the sewing machine stands |

|

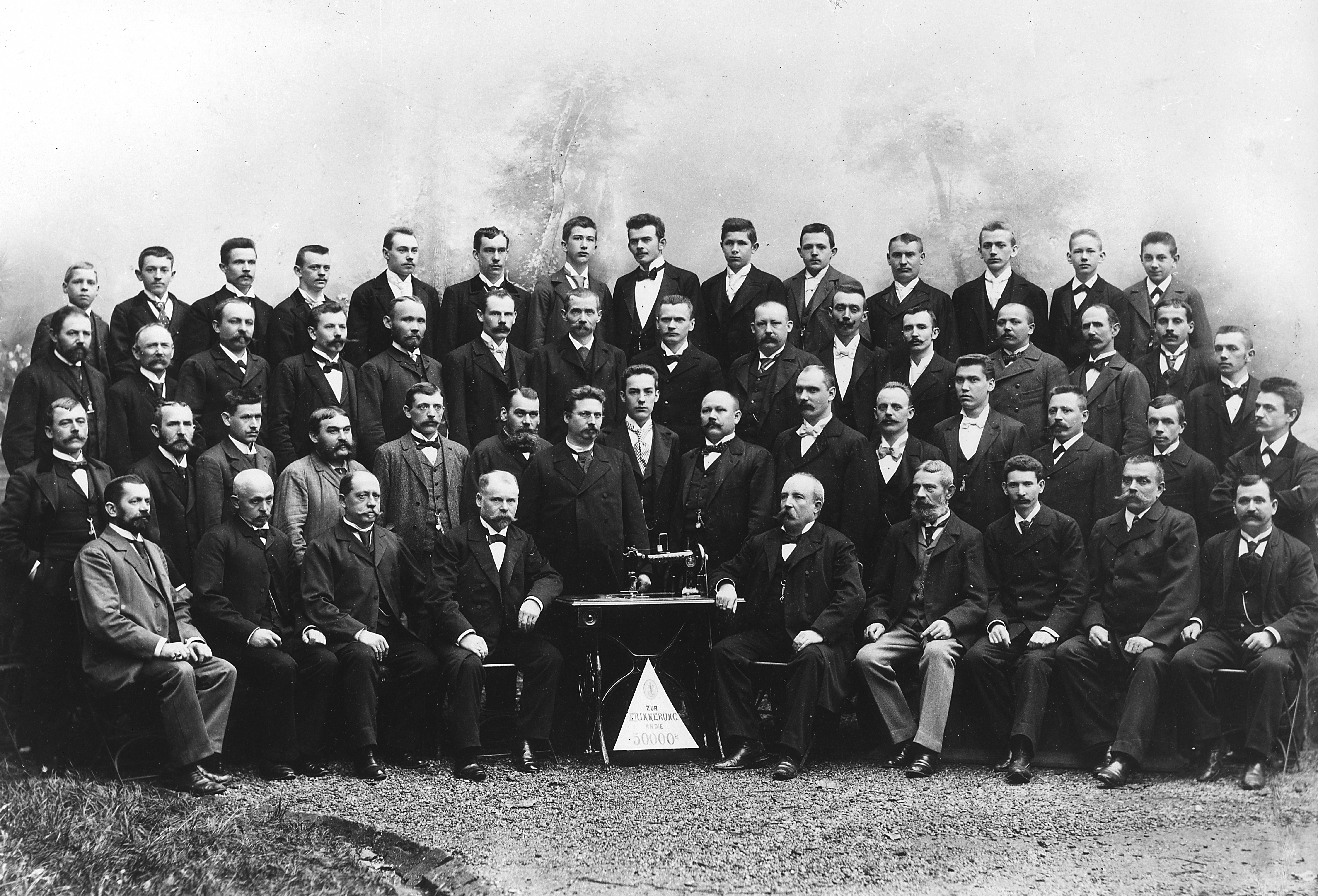

| Mr. Rezler and Mr. Komárek with their employees at celebration of 50,000th made Minerva sewing machine in Vienna, 1898 |

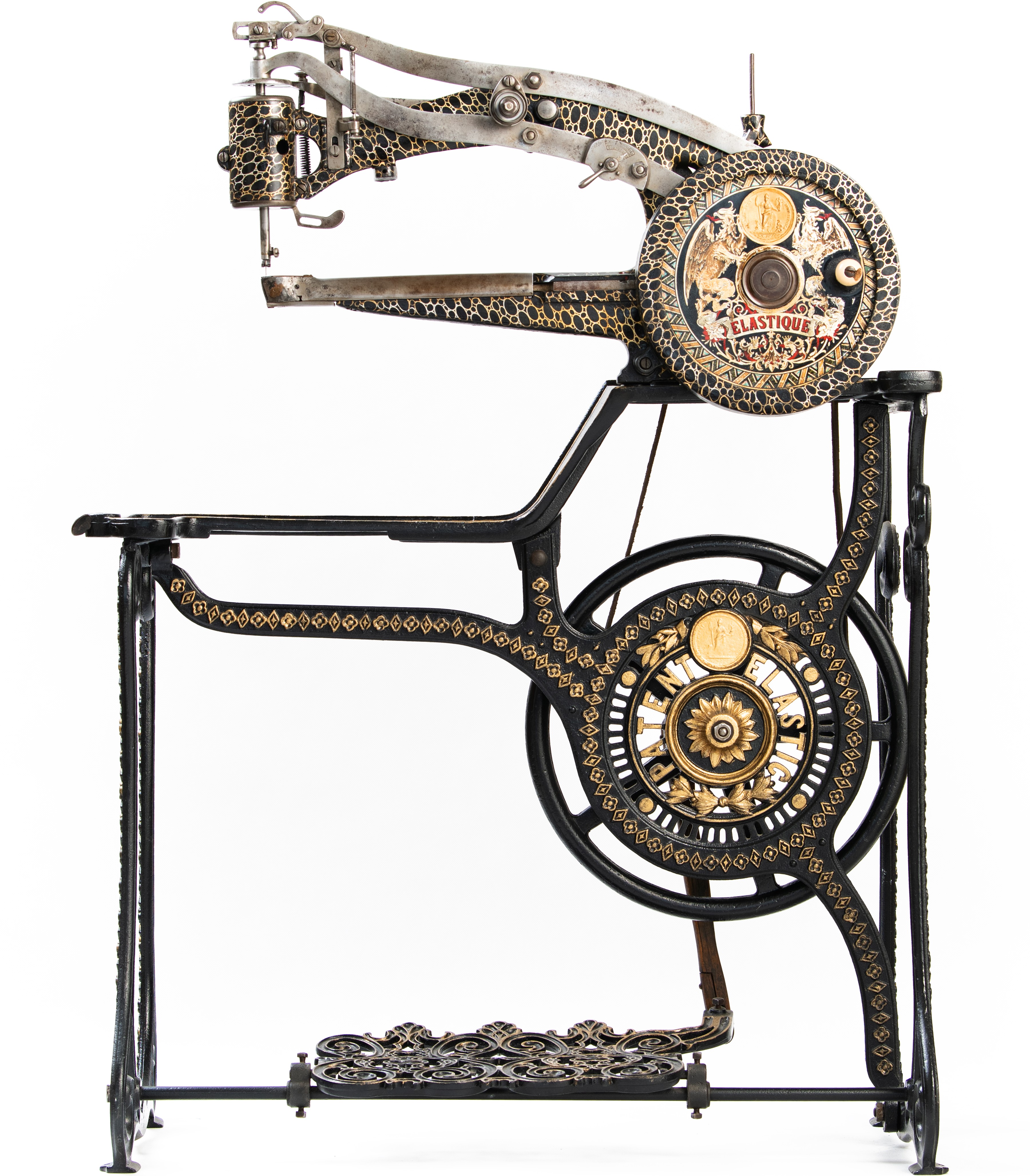

The original production program of the company consisted of professional sewing machines with a long shuttle, produced in three sizes - A, B, and C under the Howe system; and Cylinder Elastic cylinder arm machines for shoe sewing. ln 1912-13, the company Rezler & Komárek Vienna moved to Opava where it merged, due to an initiative of the Moravian agrarian and industrial bank in Brno, with a local company “Silesia - Erste osterr.-ungarische Nähmaschinenfabrik Gesellschaft E. Kohn & Mittler Opava”. After the merger of the companies a joint stock company was established and named “Minerva“, the first Austro-Hungarian factory for sewing machines, joint stock company, Rezler & Komárek”. The production was conducted solely in Opava – A, B, C machines as well as other types O, E, F; since 1924, also machines with a swinging hook, so-called “Central Bobbin”; since 1915 machines marked as M16. ln 1936, another branch factory started to be built in Boskovice at the premises of the company “Iron and steel industries a.s.” (earlier A. Eisler). The production was not sewing machine parts, but an armament production. Since 1938, there was a tendency to merge the “Minerva” in Opava with the “Iron and steel industries a.s.” in Boskovice and to transfer the headquarters from Opava to Boskovice; regardless all efforts, it did not take place that year.

|

|

|

|

| Minerva A | Minerva B | Minerva C | Cylinder - Elastic |

ln October 1938, after the Sudeten had been annexed, a part of the employees from Opava was transferred and a part of the machinery was relocated to Boskovice. New production workshops and flats for employees started to be built. ln 1938, the first household sewing machines M16 were assembled in Boskovice. ln 1940-41, the first sewing machine marked MINERVA M21 was produced in Boskovice. ln the middle of 1941, the household sewing machine production in Boskovice was discontinued, and all machine equipment was converted into the armament production for the German Wehrmacht. ln 1945, after the liberation, the household sewing machine production was restarted both in Opava and in Boskovice. Both factories were nationalized and national administration was introduced in them. The quantity of 490 sewing machines M21 were assembled in Boskovice. ln 1946, the MILA company for sewing machine production was established as a national enterprise in Opava; it associated all producers of sewing machines in Czechoslovakia. MINERVA Opava and Lada Soběslav were the first to become its parts, and a year later, also the factory MINERVA BOSKOVICE, which was then a part of the company “Iron, steel and machine industries” Boskovice. As of 1 January, 1950, independent national enterprises Minerva Opava, Lada Soběslav, and MINERVA BOSKOVICE were established. The sewing machines were produced paralelly both in Opava and in Boskovice till 1953, when, in accordance with the decree issued by the Ministry of heavy industry, the sewing machine production was transferred from Minerva Opava to the national enterprise MINERVA BOSKOVICE.

|

|

|

|

| Minerva 122 | Minerva 126-2 | Minerva 126-3 | Minerva 129 |

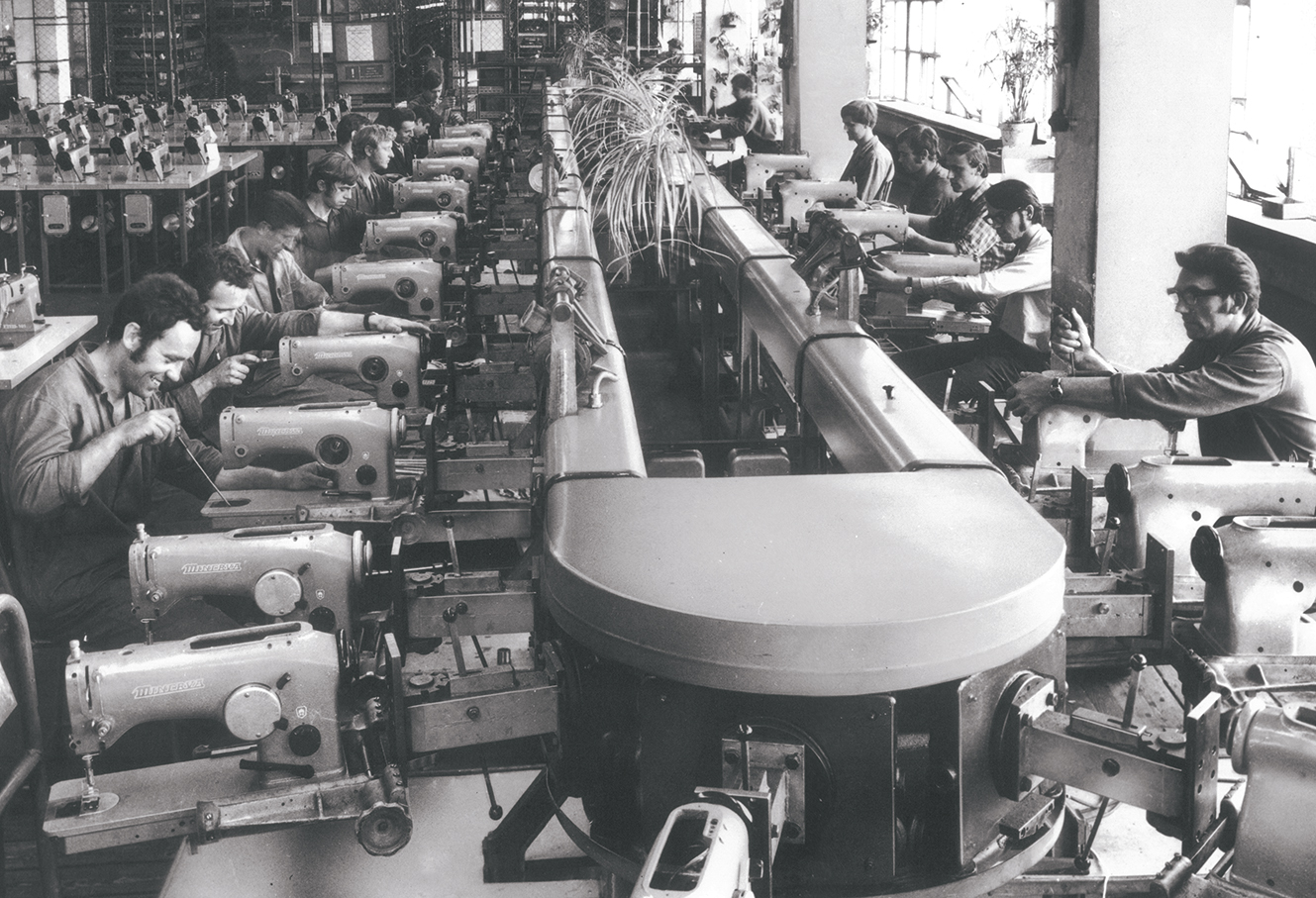

The year 1953 was significant for the company since the production started in Boskovice of industrial sewing machines transferred from the company ZPS Gottwaldov (now Zlín). The household and industrial sewing machines were produced parallely up to 1968 when the production of the household sewing machines in Boskovice was discontinued. ln 1976, a concern company ELITEX BOSKOVICE was newly established and integrated in ELITEX LIBEREC, a textile industry concern. ln 1988, the company was separated from the concern, and re-named to a state enterprise MINERVA BOSKOVICE. ln 1989, a new production workshop was built for cast iron machining and painting; then a central boiler room for fossile fuel, and a factory canteen were put in operation. At the end of 1990, a joint stock company was founded through the decision of the Minister of engineering and electrotechnical industry, and on 1 January, 1991, it was incorporated in the Register of companies as a business company MINERVA BOSKOVICE, a.s. lt was on that day when the modern history of the company commenced.

|

| Assembly line in Minerva Boskovice, 1971 |

The modem history commences on the day 1 January, 1991, when MINERVA was incorporated in the Register of companies as a legal successor of the state enterprise, and Mr. Dušan Zábrodský became the first Chairman of the Board of Directors, Mr. Lubomír Pukl the Vice-Chairman of the Board of Directors, and Mr. Antonín Oujezdský the General Director. The company consisted of the main factory with three detached workshops in Boskovice (Bosko automat workshop, press shop, and fabrication of sub-assemblies for the Elitex concern at Hybešova Street in Boskovice, a workshop for fabrication of stretch rolls in Lhota Rapotina), which altogether provided jobs for 1,500 employees, and a factory in Prostějov (350 employees). MINERVA was subsequently privatized during the first vawe of a voucher privatization, when 283,363 shares of nominal value 1,000 CZK were sold to the total of 7,006 investment voucher owners (DIK) and to 11 investment privatization funds (IPF). The company was in a burdensome situation; the COMECON market disintegrated, MINERVA was searching for new customers, new production programs, new investment partners, and it was making its activities more effective. Dissolved were the departments of transport, machinery and construction investment department, joiner‘s workshop, safeguarding service; these service departments were outsourced.

|

| General view of factory premises, 2017 |

To support the sale of sewing machines, joint ventures were established in Rovno, Saratov, and Leningrad (now Sankt Peterburg) in the countries of the former Soviet Union. Professional sewing machines M 113, M 106, M524 were developed, but they did not improve the sales situation. By the end of 1991, Mr. Antonín Oujezdský left the position of General Director on his own request, and the Board of Directors appointed Mr. Lubomír Pukl General Director as of 1 January, 1992. The heavy economic situation continued as well as a sale of unnecessary property, such as the unfinished hotel building in Dr. Snětina square; a new production shop was sold to the company Dusab s.r.o. Boskovice. The workshop at Hybešova Street in Boskovice was returned to the original owners in the restitution process. The production in the workshop was partially discontinued, partially relocated to the main factory, the same as the production of the sold workshop in Lhota Rapotina. Also vacation facilities in the villages of Suchý and Malá Morávka were sold off. Even in that complicated period, a medical center upstairs the company canteen was successfully opened. The Dutch company IMCA (lnternationale Maschinenhandel voor de Confectioeindustrie) b.v. Haarlem entered the process; it obtained exclusivity of sale in the West markets of the sewing machines produced by Minerva Boskovice. To execute the plan, a joint venture Global Trading, s.r.o. came into existence. Cooperation continued with the German company Ouick Rotan, which transferred to Boskovice a complete production of clutch motors for sewing machines. The former joiner‘s workshop was hired to a German company Novibra Süssen for production and assembly of loom spindles; the production was started of warp knotting machines for the Oskar Fischer company. The efforts to find reliable foreign partners for the production cooperation was successfully accomplished on 7 May, 1993, when a cooperation contract was signed between MINERVA BOSKOVICE, a.s. and the German producer of industrial sewing machines, Dürkopp Adler AG, Bielefeld.

|

|

|

| Dürkopp Adler 767 | Dürkopp Adler 768 | Dürkopp Adler 069 |

The aggravated economic situation was still lasting. ln October 1993 the Board of Directors decided that the only possibility of reducing the high financial load due to credits and resulting interests was to sell the subsidiary joint stock company in Prostějov. MINERVA Prostějov was sold to the Dutch company IMCA b. v. Haarlem on 28 February, 1994; the latter sold it to the American company AMF REECE in 1995. Methods were sought how to increase the sales of the sewing machines. MINERVA Trading, s.r.o. was established, its main task being to sell sewing machines including service in the Czech Republic, Slovakia, and the former COMECON countries. The Typos I series sewing machines were falling behind the world standard, and that is why the Board of Directors approved in 1995 the development of a new type series of industrial sewing machines Typos lI for shoe and leather sewing. The type series Typos II consisting of flatbed and postbed machines was intended as a module construction kit system with a high interchangeability of parts between the individual types, and it became a base for the sales recovery in the shoe-making segment. The companies IMCA and Dürkopp Adler AG continued to purchase shares, and the owner‘s majority became their possession. Mr. Jindřich Arabasz was appointed General Director. The production for the company Dürkopp Adler was continuously growing, and complete machines of 270 type series started to be assembled. During 1997, the company Dürkopp Adler AG became the majority shareholder of MINERVA BOSKOVICE, a.s. with 69.14 % of the owned shares, the significant part of which was purchased from the company IMCA. Through this relation, MINERVA BOSKOVICE, a.s. became one of the members of the group of companies Dürkopp Adler AG. MINERVA re-established its sales department again and dissolved the company MINERVA Trading. As to the company management, Mr. Rolf Bauer was appointed Chairman of the Board of Directors (the General Director‘s position was abolished). The Bosko workshop was sold off; modernized were the assembly workshop, powder painting shop, heat treatment shop; many machine tools were purchased from the company Dürkopp Adler.

|

|

.jpg) |

The investments in 1998 exceeded 160 million CZK. The trade company Global Trading, s.ro. was liquidated. The majority shareholder Dürkopp Adler AG increased the basic capital by 29.536 million CZK by subscription of a new issue of shares, and thus it possessed 83.46 % of shares of MINERVA BOSKOVICE, a.s. of the total number of 312,899 shares. The assembly of 767 type series sewing machines commenced; their production exceeded the limit of 6,000 pieces in two years. ln February 1999, Mr. Pukl replaced Mr. Rolf Bauer at the position of the Chairman of the Board of Directors. The SAP R/3 information system started to be implemented; transfers of production and assembly of other machines from DA (069 and 269 types) continued; and the production commenced of the first machines of Typos lI series. The MINERVA trademark was discontinued. ln 1999 both Typos lI and Typos I machines were launched on the market under the German trademark of Dürkopp Adler.

|

|

|

| Dürkopp Adler Typos II 1180-547 | Dürkopp Adler Typos II 4180-547 | Dürkopp Adler Typos II 4280-647 |

|

|

|

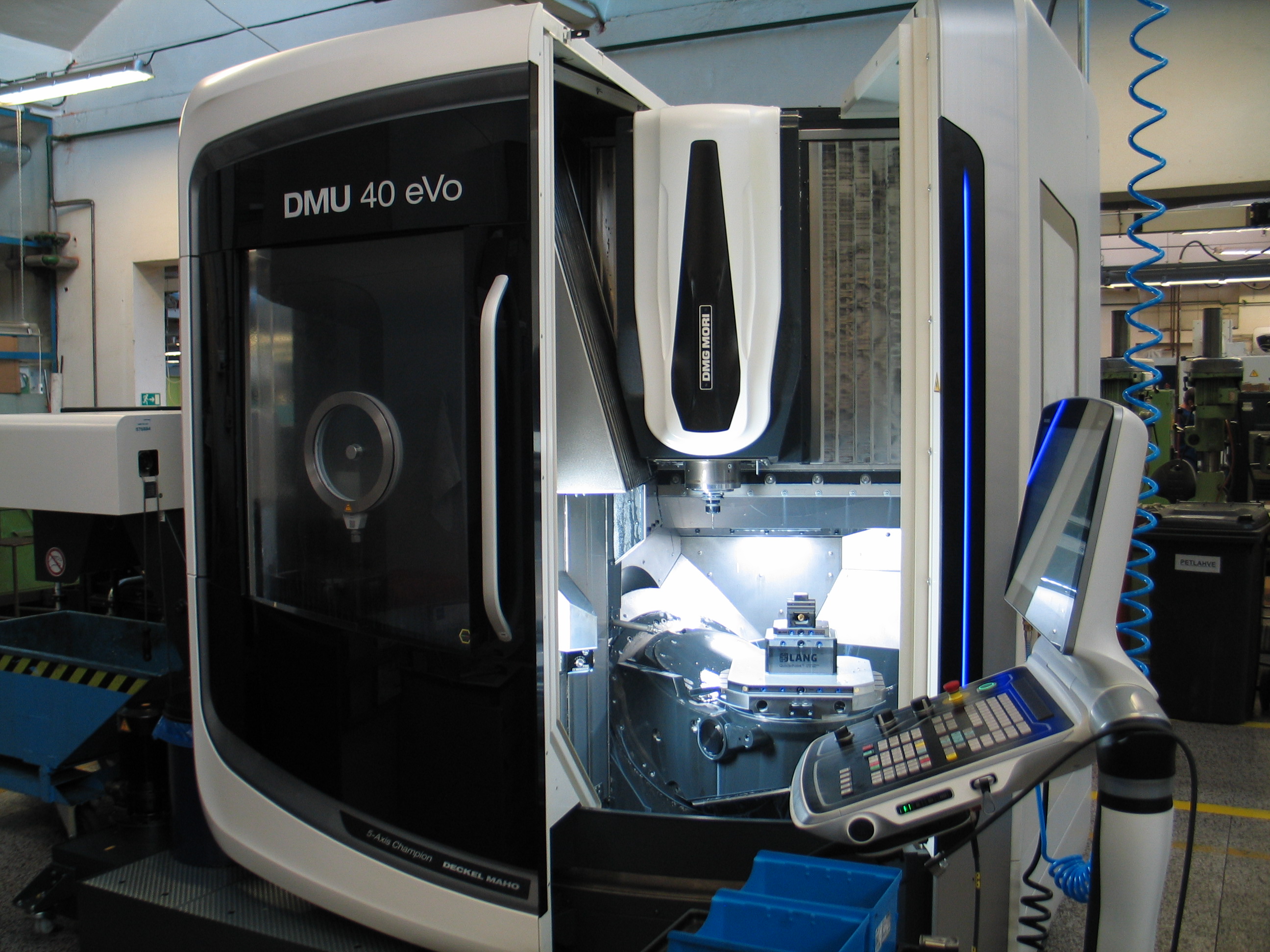

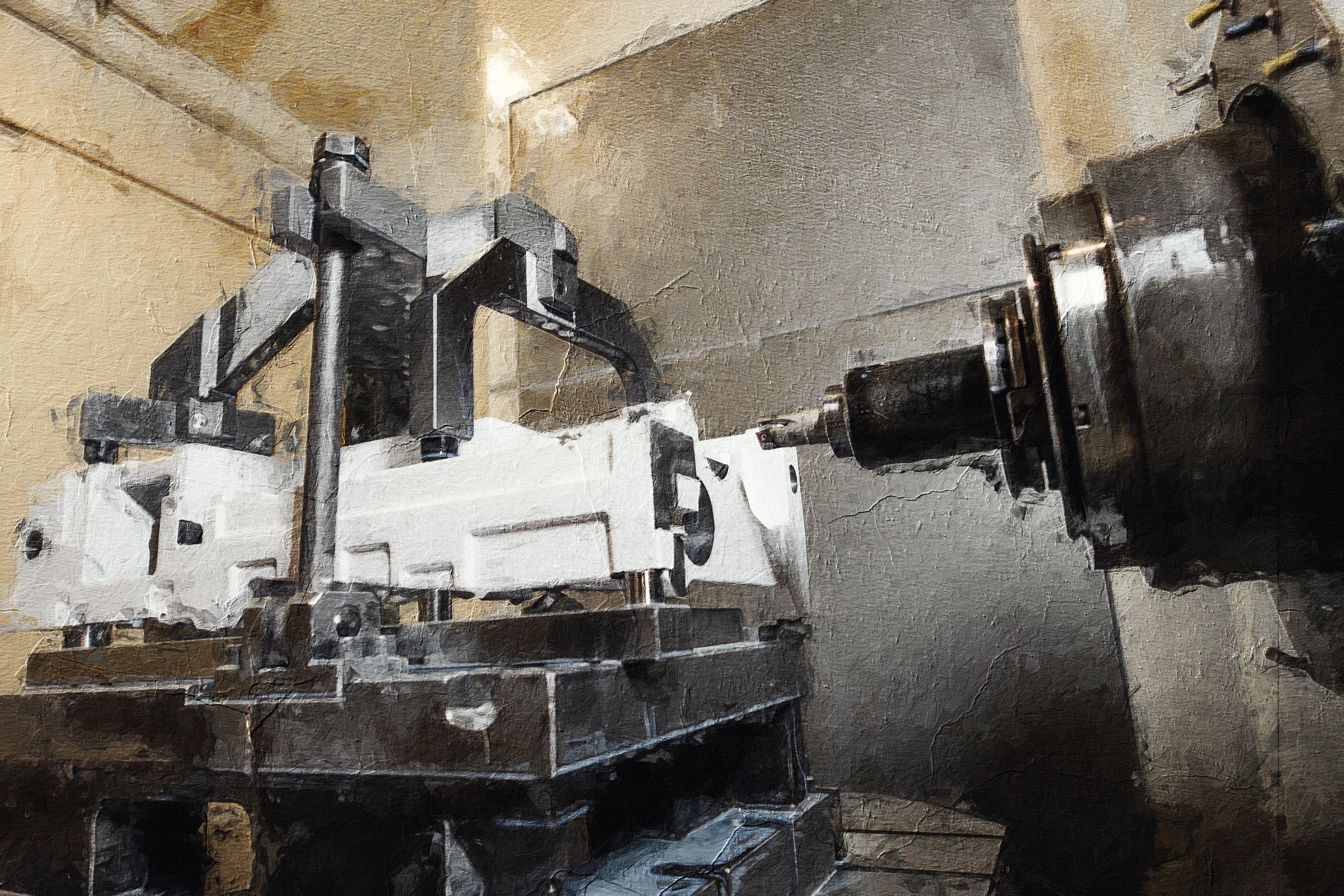

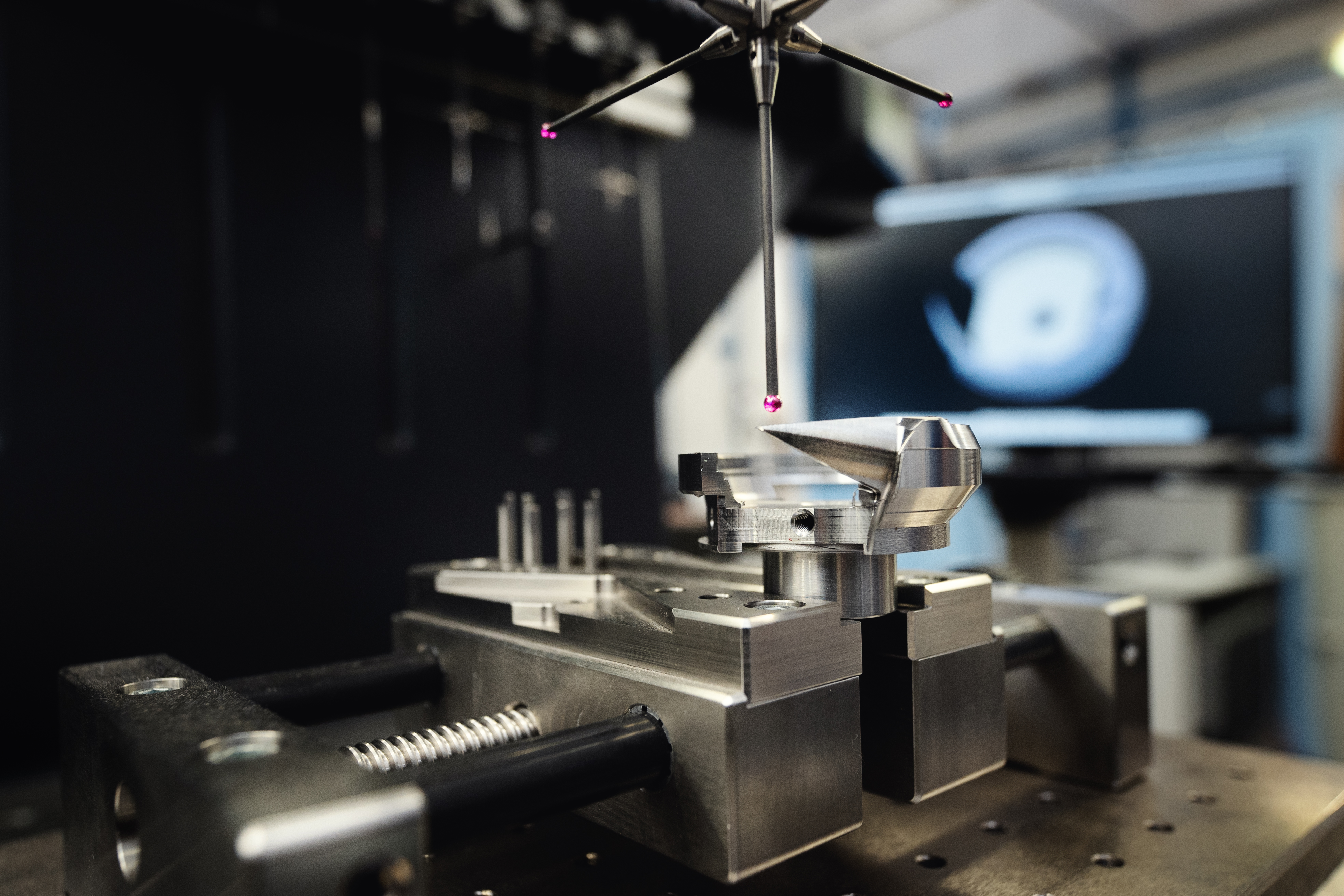

ln 2000 Mr. Miroslav Ošťádal took the position of the Chairman of the Board of Directors. Production transfers of other machines from DA (204,205,275,381,382,697 and 768) were carried out. The turnover exceeded 1 milliard CZK. MINERVA BOSKOVICE, a.s. took the 15th place in the competition "Exporter of the year"announced by the Chamber of commerce of the Czech Republic. The quality certification was executed in accordance with the international standard EN ISO 9001: 1994; the certification was conducted by the BVQI company. The factory modernization continued, a storehouse of finished products was adapted, packing and dispatch shops and existing individual offices of the development design were gathered in a modem open-space office. By the end of the year, 3 workstations with CAD CATIA system were installed; as a result, conditions were established of an effective cooperation in the development of industrial sewing machines between the companies Dürkopp Adler AG and MINERVA BOSKOVICE, a.s. ln 2001 the company achieved the turnover of 1,194 million CZK, almost at the same amount as in 2000, and provided jobs for 1,106 employees. The years 2000 - 2001 were among the best years in the modern history in aspect of turnover and staff number. More than 24 thousand sewing machines were produced every year; over 20 thousand thereof for the company Dürkopp Adler, and over 3 thousand pieces were the shoe sewing machines. The development of the sewing machines of Typos lI series was accomplished, and the development of a new M-Type series started to be planned. ln 2002 the assembly of sewing machines of 271 type was transferred to DARO in Romania, a new factory under the concern Dürkopp Adler AG. The galvanizing shop reconstruction was completed. The production dropped that year, which continued in the following three years. ln 2003 Mr. Alfred Wadle took the position of the Chairman of the Board of Directors with the focus on the sales increase of the shoe sewing machines and enhancing the key competences of Minerva Boskovice. The commercial department was re-organized, the development, grey cast iron machining with painting and assembly became the key competences.

|

|

|

The press shop and tool making shop were outsourced and taken over by the company H&P POLY-TECH, s.r.o. in 2004. ln 2005 a rotation machining was centralized and made more effective. Following the sale of three houses and a reception building in Sokolská Street was the reconstruction of the existing building of the commercial department, and a new showroom, training room, offices of HR department, reception, and cash office were established on its ground floor. On the first floor, next to the offices of the commercial and logistics departments, offices of the financial accounting and controlling departments were established. The first 8 sub-classes of a new M-Type series were released for production: they were sewing machines of 867 type. Production transfers from the company Dürkopp Adler AG Bielefeld continued, especially machining and painting of grey cast iron rough castings, and production of sewing equipment parts. Nevertheless, the drop of production and sales was going on. On 1 July, 2005 the Dürkopp Adler AG company‘s majority of shares was taken over by the Chinese company ShangGong Europe Holding Corp. GmbH, and MINERVA BOSKOVICE, a.s. became a part of this multinational group of companies. ln 2006 the factory reconstruction and modernization continued with the aim of the production concentration and clearing up of unnecessary premises. A new central storehouse of purchased products and own semi-products was built up; it collected in one place the purchased materials and produced parts from side-storehouses in the assembly departments.The commercial users of the M-Type machines were found out, the company was recovering, the turnover was increasing, and jobs were stabilized. Mr. František Hrda was appointed Chairman of the Board of Directors. The recovery process also continued in 2007. The staff number achieved 813 employees. Minerva obtained a subsidy from the Ministry of industry and commerce for the development of M-Type shoe-sewing machines for demanding clients; the type series of zig-zag sewing machines was innovated. A slight growth continued also at the beginning of 2008. At the end of the first half-year, suddenly a drop of production and sales occurred in all segments as a result of the world economic crisis, which in full appeared in 2009. The turnover dropped under 50 %, employees with a time-limited contract left the company; the number of employees was reduced under 500. Tough economical measures were taken, and solely due to them and thank to financial assistance provided by the parent company the crisis was successfully overcome. The company H&P POLY-TECH, s.r.o. did not withstand the crisis. The company was declared bankrupt and MINERVA took a part of their activities back. At the end of the year an extraordinary General meeting of shareholders approved an increase of the company‘s basic capitaI by 100 million CZK, which was effected by offsetting the Dürkopp Adler company‘s receivables against the company MINERVA BOSKOVICE.

|

.jpg) |

|

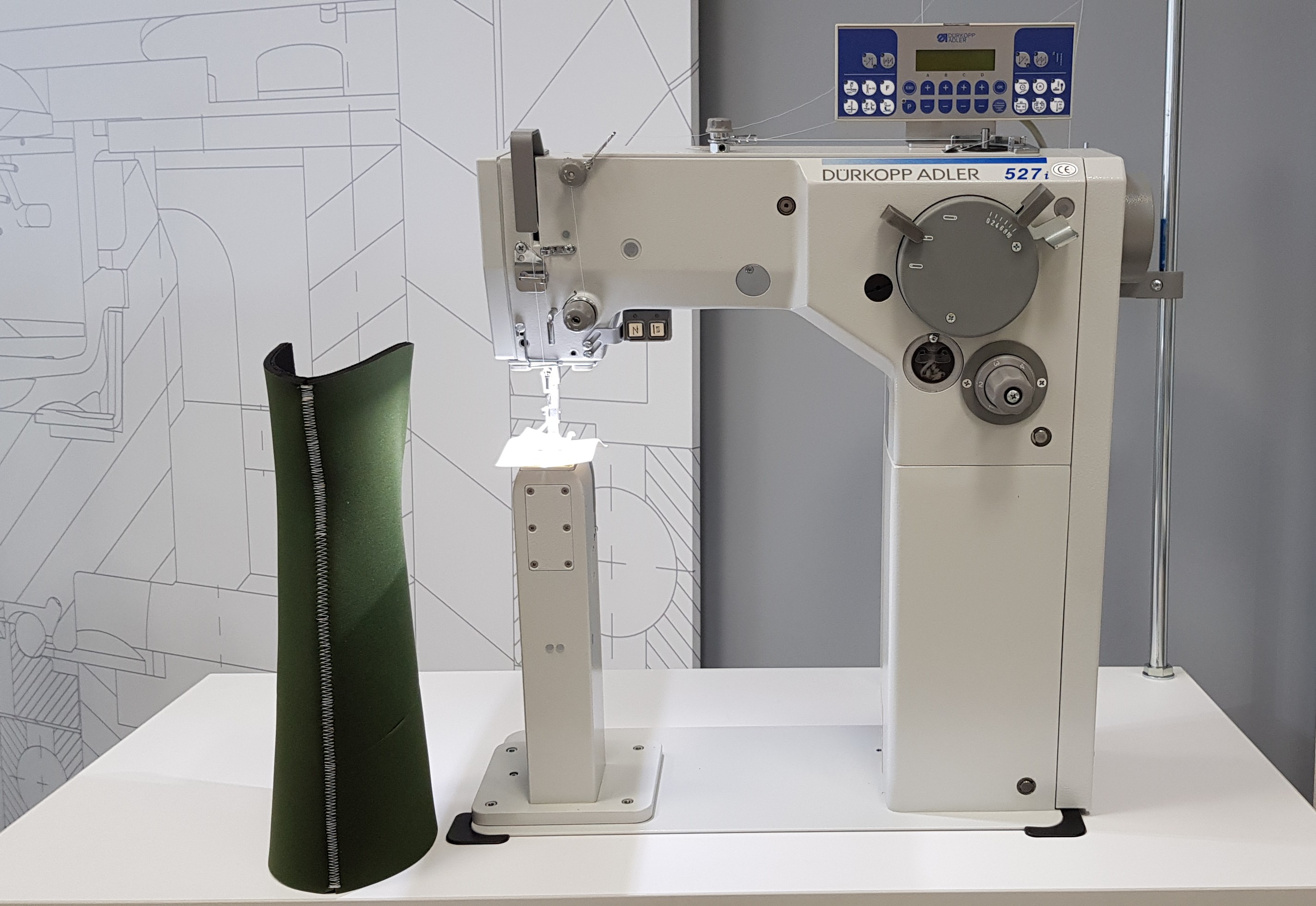

| Dürkopp Adler ZZ 525i-847-750 mm | Sewing operations on a zigzag stitch machine | Dürkopp Adler ZZ 527i-847 HP 294 mm |

After the crisis year 2009, which MINERVA survived with a significant loss, the economic situation was gradually improving. The year 2010 was significant by an increase of the production volume and the related increase of staff number. Within half a year the production was doubled. At the same time, as a result of the technical team‘s systematic work, the company internal costs were reduced and work productivity increased. The year 2011 kept to the previous year‘s positive trend. Almost 16,500 machines were supposed to be produced and thus to comply with the customers‘ particular requirements. MINERVA as a member of the Dürkopp Adler concern was the largest production company with the key competences in sewing machine assembly, machining of castings, and painting. The sewing machines produced in MINERVA are used in the companies of renowned brands (Bata, Adidas, RIEKER, GABOR, RICOSTA, MEINDL, Högl, ARA, LLOYD, etc.).

|

|

|

Minerva Boskovice saw a major increase in demand for its products in the previous two years, which led to a boost in production and sales in 2015 and a continuous extension of production capacities. Every month there was a growth in production and cooperation; the head count increased and the company laid emphasis on a quick installation and consistent use of new investments.Turnovers totalled 1,131 thousand CZK, the highest since 2001. The planned turnovers of 2015 were exceeded by 33% and those of 2014 by 23%. The year 2019 came to a close. From the perspective of the previous periods, it was a milestone for Minerva. After several years of economic growth, there was a decline in turnover and production. Beginning in the second half of 2019, there was a major drop in orders, especially in the medium-type for automotive sewing. The company responded to this by reducing production volumes and costs, reducing staff numbers and restricting expenditure in investment and inventory. The total turnover from the sale of its own products, services and materials was 1,206 million CZK, a decrease of 216 million CZK in comparison with 2018. A total of 18,764 industrial sewing machines were sold, by 6,855 less than in the previous year. In 2019 we presented a shoe column sewing machine with a short thread trimmer at the trade fair in Milan, Italy. In Frankfurt am Main and in Shanghai it was a brand-new product, the M-Type Delta sewing machine.

|

|

|

|

|

|

| Dürkopp Adler 887-353922 | Sewing operations on a machine with material trimming | Dürkopp Adler 868-190922 |

The year 2020 was exceptional in many aspects. The whole year was influenced by the global pandemic, which also affected the Czech Republic. Extraordinary government measures slowed down and limited the activities of companies and people as a result of the proclaimed state of emergency and implementation of further measures in two waves in March and then in September.Despite all these difficulties, Minerva consistently fulfilled the intragroup production requirements as well as the customer’s requirements in the shoe segment in the first half of the year. The virus had a considerable impact on our business partners as well, and that led to a decrease in orders from July, resulting in a drop in production volumes. Legal obstacles on the part of employer led the company to reduce the shift operation and the five-day work week scheme in July, August and September, when the staff stayed at home and received reduced wages. To compensate for this, Minerva drew 60% compensation on these wages from Antivirus B, a government subsidy programme. This meant that there was no need to reduce the primary staff numbers. New orders began to inflow at the end of September and continued till the end of 2020. In 2023, it was decided to build a new production hall, which was successfully completed at the end of 2024.

|

|

|